Trust in technology – proven by our projects

We deliver solutions as unique as your production demands.

Whether custom manufacturing, series production, or system integration – we develop and implement technical concepts that deliver real-world results.

Our portfolio showcases selected projects and services we have implemented for companies across a wide range of industries – from high-frequency welding tools for conveyor belts to systems for hot filling. Each project stands for quality, precision, and collaborative partnership.

Experience how we turn challenges into functional technology – efficient, durable, and precisely tailored to your needs.

Fields of expertise

- Consulting and sales of radio-frequency welding systems by REG Galbiati, including in-house development and manufacturing of custom high-frequency welding tools

- Thermoforming and sealing tools including heat protection plates, frames, and chambers for packaging machines

- Manufacturing of optimized custom spare parts for machines without spare parts availability, using state-of-the-art materials and production technologies

- Piston dosing filler for hot filling of molten products and fibrous food products

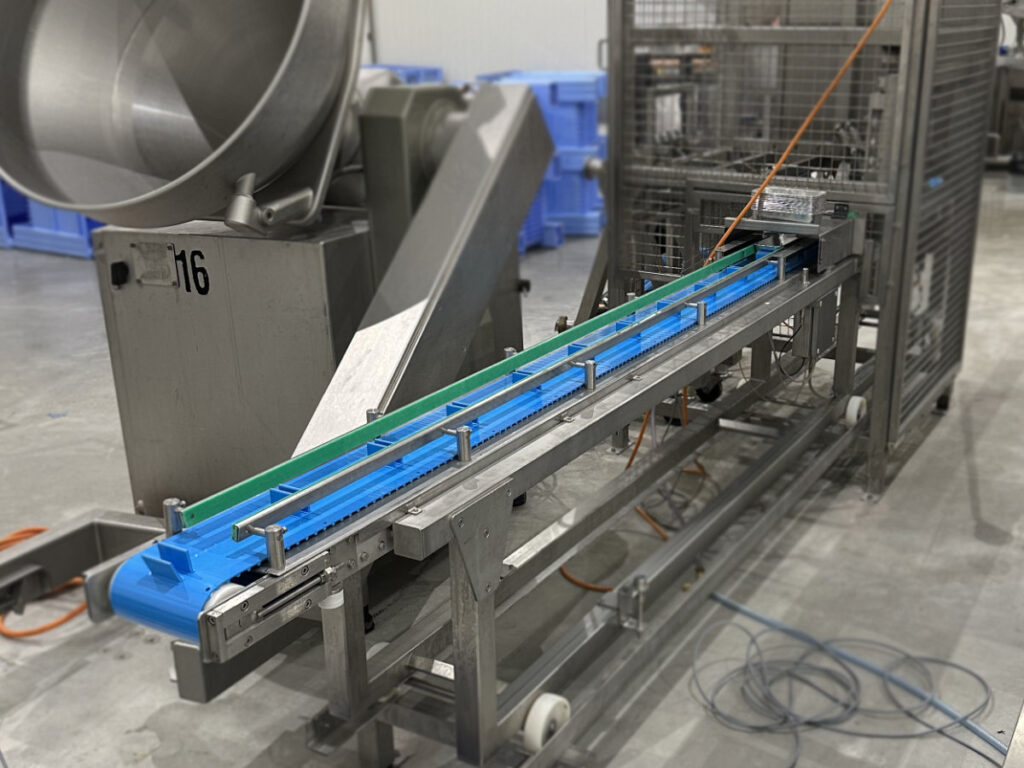

- Specialized conveyor technology, e.g. Z-elevators for cleanroom environments in food production

- Process automation; process standardization and stabilization

Heidesheimmaschinen

Heidesheimmaschinen was a manufacturer of piston dosing fillers. Specially designed for fibrous foods, doughs, and other challenging filling materials. We acquired all rights, design drawings, and spare parts inventory from the company when Mr. Dieter retired due to age. The spare parts supply is still maintained, and new dosing fillers are being developed based on the proven technology, now combined with modern drives and control systems.

Spare parts supply continues to be maintained. Building on proven technology and combining it with modern drive and control systems, new dosing fillers continue to be developed and manufactured.

Project examples

Meatloaf filling with container changeover

Filling tower for dosing meatloaf mixture into 1000g and 400g containers. The filling flow is requested by a filling machine equipped with a third-party flow distributor. The containers are positioned beneath the filling heads, which immerse into the containers and are raised during the filling process. At the end of each cycle, the flow of meat mixture is cut off, and the machine positions the containers for the next filling cycle.

The switch between 1000g and 400g containers is carried out by replacing the belt magazine insert. The spacing of the pushers on the tray conveyor and the lateral guides are specifically adjusted for each container format. The changeover can be completed within just a few minutes.

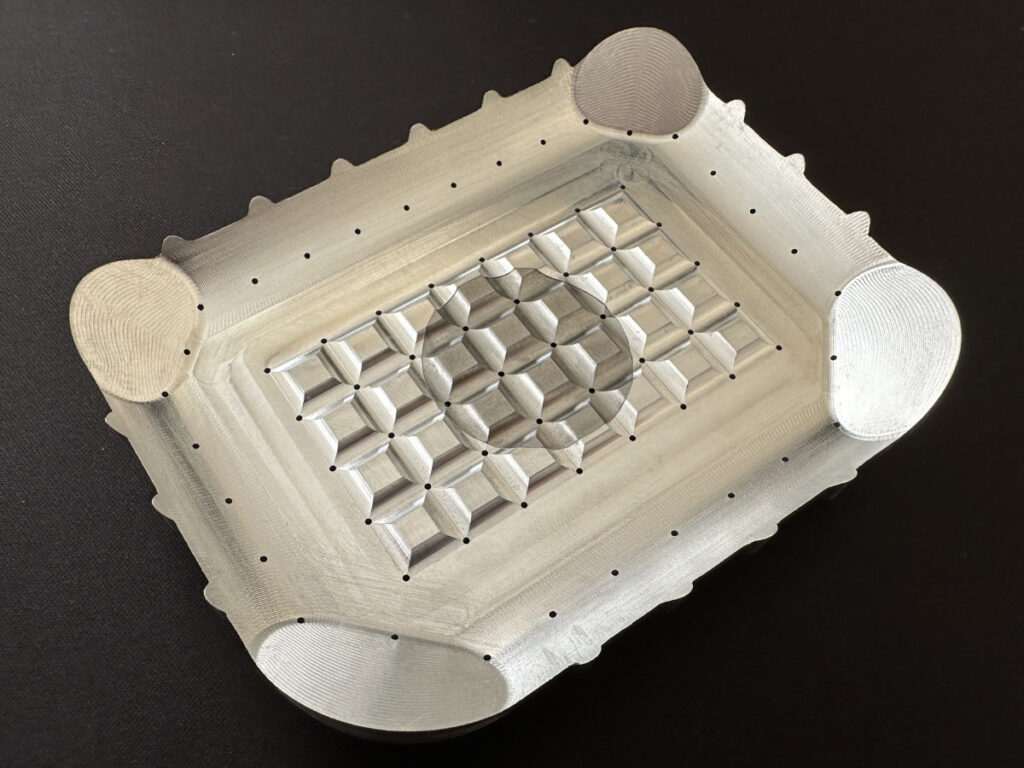

Forming base for thermoforming film packaging machine

The thermoforming insert base has been optimized compared to the original part. The number of vacuum bores has been increased and the bore diameter reduced to improve film draw-off while preventing imprint marks. A core made of ferromagnetic stainless steel has been integrated in the center, allowing the bases to be easily inserted and removed from the mold using a magnetic lifter.

Heated plate for packaging machine with special coating

Heated plate for sealing containers with film. The plate was custom-manufactured and coated with a special surface treatment that surpasses PTFE coatings in terms of mechanical durability and temperature resistance.

Heavy-duty machine transport rollers

Stainless steel version for relocating machinery within food production environments. Load capacity per unit: 2000 kg.