Radio-frequency welding & conveyor technology for industrial applications

Project examples

As a reliable partner for industrial manufacturing processes, we offer specialized services in the field of Radio-frequency welding. Our technology enables precise, durable, flexible, and cost-effective joining of thermoplastic materials – primarily in conveyor systems, but also in the automotive, packaging, medical, and textile industries.

As exclusive distribution partner of the italian company REG Galbiati in Germany, Austria, and Switzerland, we offer access to high-quality high-frequency welding systems – renowned for their precision, durability, and adaptability.

Our offering is complemented by proprietary radio-frequency welding tools we design and manufacture ourselves, as well as by auxiliary equipment and components for upstream and downstream process steps in product finishing. This means we don’t just deliver individual parts, but complete process solutions – validatable, reproducible, stable, and efficient.

Overview of our services

- Radio-frequency welding technology for industrial series and custom production

- Technical consulting, sales, and after-sales service for radio-frequency welding machines from REG Galbiati

- Project support from planning and design to commissioning

- Maintenance, spare parts supply, and system optimization for existing installations

- Custom radio-frequency welding tools – including modular designs – as well as matching lower tools with any form-fit or guide-track profile

Why work with us?

- Extensive experience in processing TPU plastics – especially in conveyor technology

- Technical expertise combined with practical, solution-oriented consulting – for results that work in real-world production

- Direct access to innovative radio-frequency welding systems from the renowned Italian manufacturer REG Galbiati

- Tailor-made solutions– precisely aligned with your individual production requirements

Choose a partner who understands your processes – and helps you evolve them.

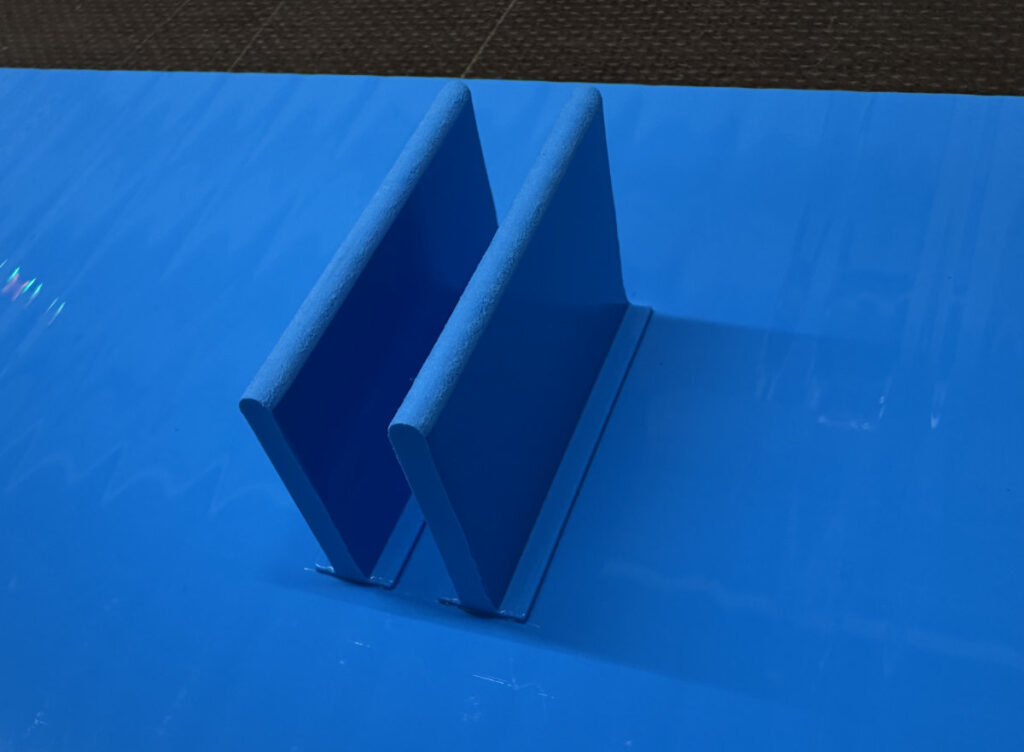

"Modular T-cleat tool; T-shaped cleat formed in the radio-frequency welding process.

The tool length is modularly adjustable and can therefore be used even between corrugation edges with only 5 mm lateral distance to the apex. The tool can also be used for preformed T-cleat.

In addition, the tool can be easily converted – with only a few accessory parts – for welding smooth studs.